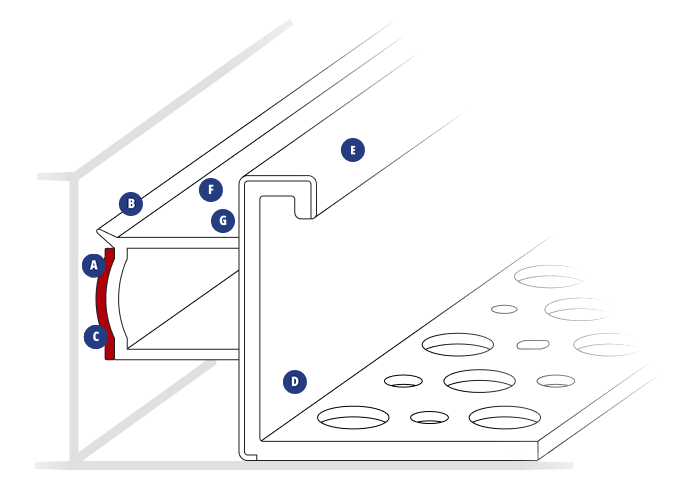

The Revolutionary caulk-less Casing Bead

The ultimate self-adhering casing bead, offering a robust weatherproof seal with Shark Fin Technology. Save time and cost with this innovative solution. Discover more and transform your builds!

Featured in 3 colors to match window or door finishes.

White

Gray

Tan

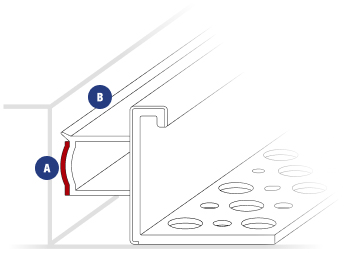

High Bond Adhesive - 3M

Strongly adheres to any clean, smooth attachment surface creating a durable, long lasting bond.

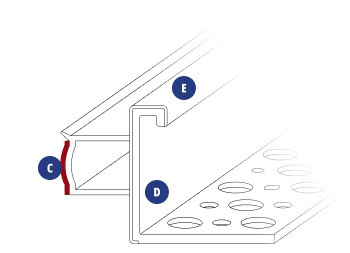

Caulk-less Innovation

A flexible gasket provides a smooth finished look without requiring caulk, saving time and money.

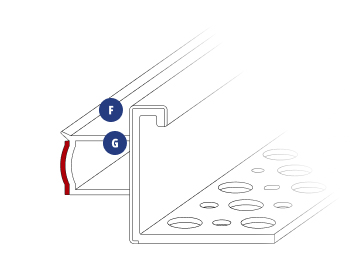

Shark Fin Technology

Unique integrated fin provides a seamless transition to the adhesion surface ensuring a perfect seal.

CUT, PEEL, STICK–IT’s that fast!

Transform your construction experience with SPEED BEAD. A simple solution that saves time and money, requires no caulk or backer rod, and ensures a perfect seal every time.

Speed Bead savings calculator

See how SPEED BEAD can effortlessly reduce your expenses.

Simply enter the number of windows in your next project?

Please note: Based on windows only, 3'×5'.

Your est. savings

For estimation only & may not accurately reflect regional labor & material cost. *If standard bead and backer rod are installed correctly Sealants meet the requirements of ASTM C-794 Adhesion-in-Peel of Elastomeric Joint Sealants.

What our customers are saying...

Contractor Testimonial & Product Features for SPEED BEAD

Contractor Window & Door Application for SPEED BEAD

INSTRUCTIONS & TOOLS

SPEED BEAD can withstand extreme temperatures.

Performs at –40 to 212F degrees. While the product has a great initial bond, the product will be fully set in 24 hours. Allowing the adhesive bead to be repositioned if necessary.

Recommended Tools:

- Multi-purpose Trim Shears

- Isopropyl Alcohol

- Tape Measure

- Wiping Cloth

- Utility Knife

Install Instructions:

-

CLEAN SURFACE

Clean the surface with a wiping cloth and isopropyl alcohol to remove any dirt or soil that may be on the surface.

-

MEASURE & CUT CASING BEAD

Measure the vertical surfaces first and add an additional 3/8th inch overhang for each corner. Then, measure the horizontal surfaces and add 5/8″ inches to each side before cutting. Use multi-purpose trim shears to cut casing bead.

-

REMOVE NOTCH FROM HORIZONTAL CUT

Carefully use a utility knife and notch out 5/8th inch of the flexible bulb. This will provide clearance for the vertical piece of casing bead.

-

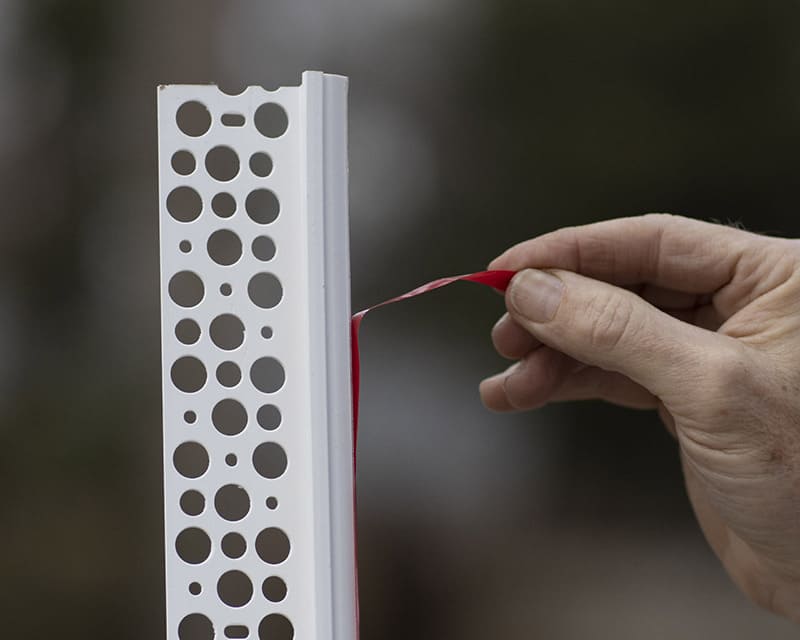

APPLY SPEED BEAD TO OPENING

Peel off the protective tape covering the adhesive and apply the SPEED BEAD to the surface. We recommend starting at the bottom to make sure the casing bead is perfectly trimmed.

-

APPLY FIRM PRESSURE

Align the casing bead in the proper position. Then firmly apply pressure and push into place for proper adhesion. Gently tug on the casing bead to make sure it has properly adhered.

-

CHECK FOR CORNER GAPS

You will want to then check the corners for any gaps where water may enter. We recommend that you apply a small amount of approved sealant into each of the corner joints to ensure they are properly sealed.

360º Product View:

For more information about SPEED BEAD or to speak with an AMICO Sales representative

Contact us

SPEED BEAD TESTED & approved

The AMICO SPEED BEAD product achieved passing results found on pages 3-4 of this test report when tested in accordance with the ASTM E330/E330M, ASTM E331 and ASTM E283.

Structural Performance Test

ASTM E330/E33M

Standard Test Method for Structural Performance of Exterior Window, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference

Water Penetration Test

ASTM E331-00

Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference

Rate of Air Leakage Test

ASTM E283-04

Standard Test Method for Determining Air Leakage Rate Through Exterior Windows, Curtain Walls, Doors by Specified Pressure Differences Across Specimen.