Finish Characteristics

Finish Pros and Cons

Fluoropolymer Paints

PROS

- Broad color pallet

- Mica and Metallic options

- Easy color matching

- Can close match to anodizing with better color consistency

CONS

- Thin application

- Getting to longer warranty will require 3-4 coat products and thus cost more

Powder Coating

PROS

- Durable, thick covering

- No VOC

- Hides imperfections in metal

CONS

- Bright colors tend to be less color stable

- Limited color pallet

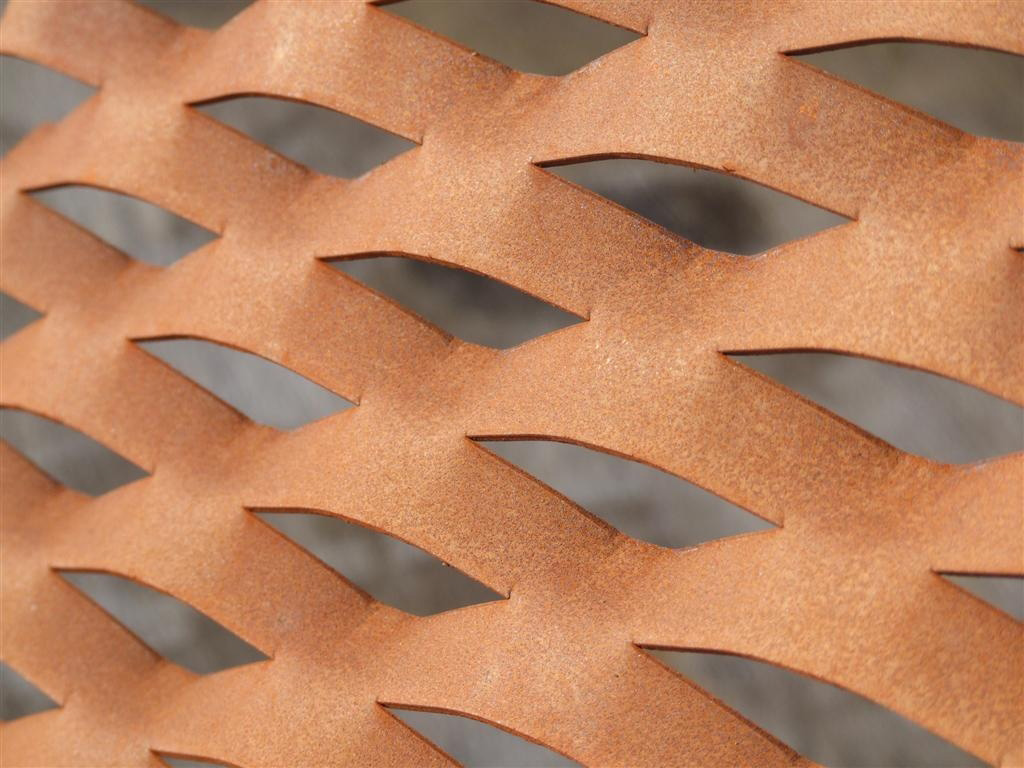

Natural Finishes

PROS

- No added finish

- No fading or damage problems

- Rich natural finishes

CONS

- Higher initial material cost

- Less control of aesthetic details

- Changes over time

Selecting a type of finish can be difficult; below are suggested steps to help define key variables that will narrow your selection process.

At anytime in your design process, if you have questions and would like to discuss your projects, feel free to schedule a quick consultation with us here at AMICO using our Calendly tool to discuss your project.

DEFINE YOUR IDEAL COLOR

If having an exact color match is critical to your design, you may want to consider paint because it can be mixed to make a custom match.

DEFINE YOUR ACCEPTABLE SHEEN

If a flatter finish is not acceptable, you will want to look at powder coating that can provide a higher sheen or anodizing to achieve a more metallic appearance.

DEFINE YOUR ACCEPTABLE WARRANTY

AMICO’s finish warranty is defined by the manufacturer of the product selected. Their warranties are defined by the AAMA Standards that measure color shift and gloss retention:

- 2603 Grade = 1 year,

- 2604 Grade = 5-10 year

- 2605 Grade = 10-20 year

Finish FAQ's

Unfortunately, the answer is, that it depends. Prices change frequently, and grades within each finish vary widely. The best first step is to define the color, sheen desire, and warranty requirements and then discuss your project with AMICO team for quoting and budgeting. Schedule a call with AMICO now.

Cleaning and maintaining of AMICO products are simple and straightforward. Often, mild soaps and detergents applied with a sponge or bristled brush is more than adequate. The frequency of cleaning will vary from location to location. Installations exposed to more smog, less rainfall, or salt spray will require a more frequent cleaning regimen. Below are links to some thorough cleaning guidelines from manufacturers and the AAMA.

Painted and Anodized Aluminum Surface Maintenance and Cleaning:

The AAMA has some specific guidelines for the care of architectural metal products before installation and after installation.

Powder-Coated Aluminum Surface Maintenance and Cleaning:

Each manufacturer has its own detailed cleaning and maintenance guidelines, though they are similar. Linked below is a maintenance guide from Tiger Drylac, a leader in powder coating products.

![]() Download Tiger Drylac Cleaning and Maintenance Guide Here

Download Tiger Drylac Cleaning and Maintenance Guide Here

Cleaning Precautions:

- Correctly identify the aluminum finish to be cleaned when selecting an appropriate cleaning method.

- Never use aggressive alkaline or acid cleaners on aluminum finishes.

- Do not use cleaners containing trisodium phosphate, phosphoric acid, hydrochloric acid, hydrofluoric acid, fluorides, or similar compounds,

- Strong solvents or abrasive cleaners can cause damage to painted surfaces

- Test clean a small section first

- Do not mix cleaners

- Clean metal while it is shaded. Do not clean metal when it is hot; also avoid cleaning in freezing temperatures. Surfaces cleaned in these adverse conditions will streak or become tainted and will not restore to their original appearance.

- Do not use wire brushes, steel wool, sandpaper, abrasives or other similar cleaning tools, which will mechanically abrade the coating surface.

- Do not use excessive abrasive rubbing to remove stubborn stains.

- NOTE: Care should be taken to avoid overspray or run off of cleaner onto other building components such as glazing materials or sealants.

You can visit their websites for the major suppliers below and see their ever growing pallets product offerings. If this feels overwhelming, no problem, schedule a call with AMICO now and we would love to help you walk through a finish selection process.

Major

Supplier

Brands

FLUOROPOLYMER PAINTS

POWDER COAT

FLUOROPOLYMER PAINTS

FLUOROPOLYMER PAINTS

POWDER COAT

FLUOROPOLYMER PAINTS