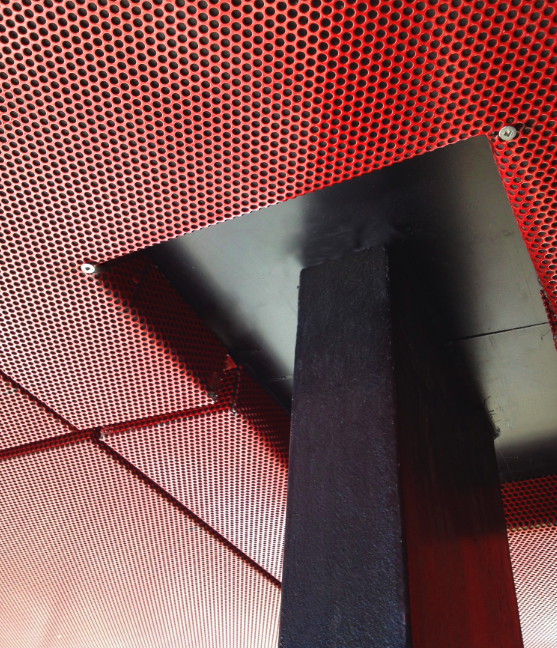

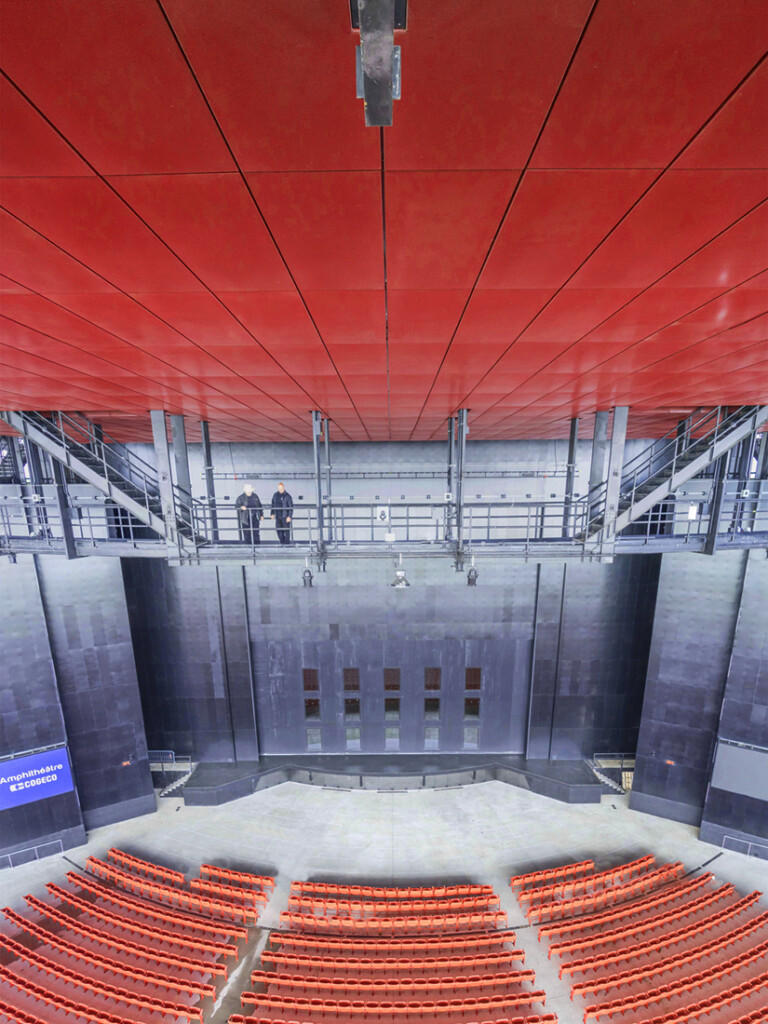

Alone, or paired with sound dampening backer, perforated metal plays an active or purely passive role in eliminating specific frequencies in sound–filtering systems.

This can be beneficial for auditoriums, places that require a large gathering like airports or schools, or enclosures for loud equipment like HVAC & compressors.

Here are a few benefits of perforated metal acoustic panels to consider:

- Perforated holes are easily customized to meet the detailed frequency needs of a given application.