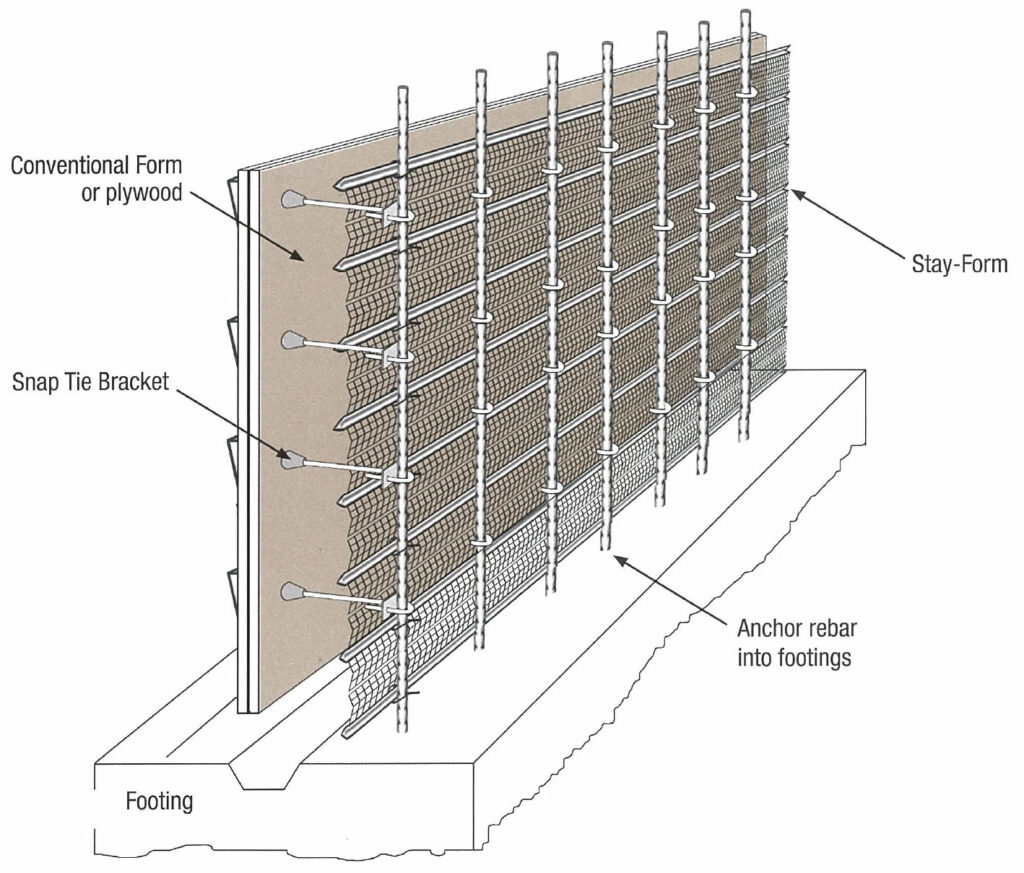

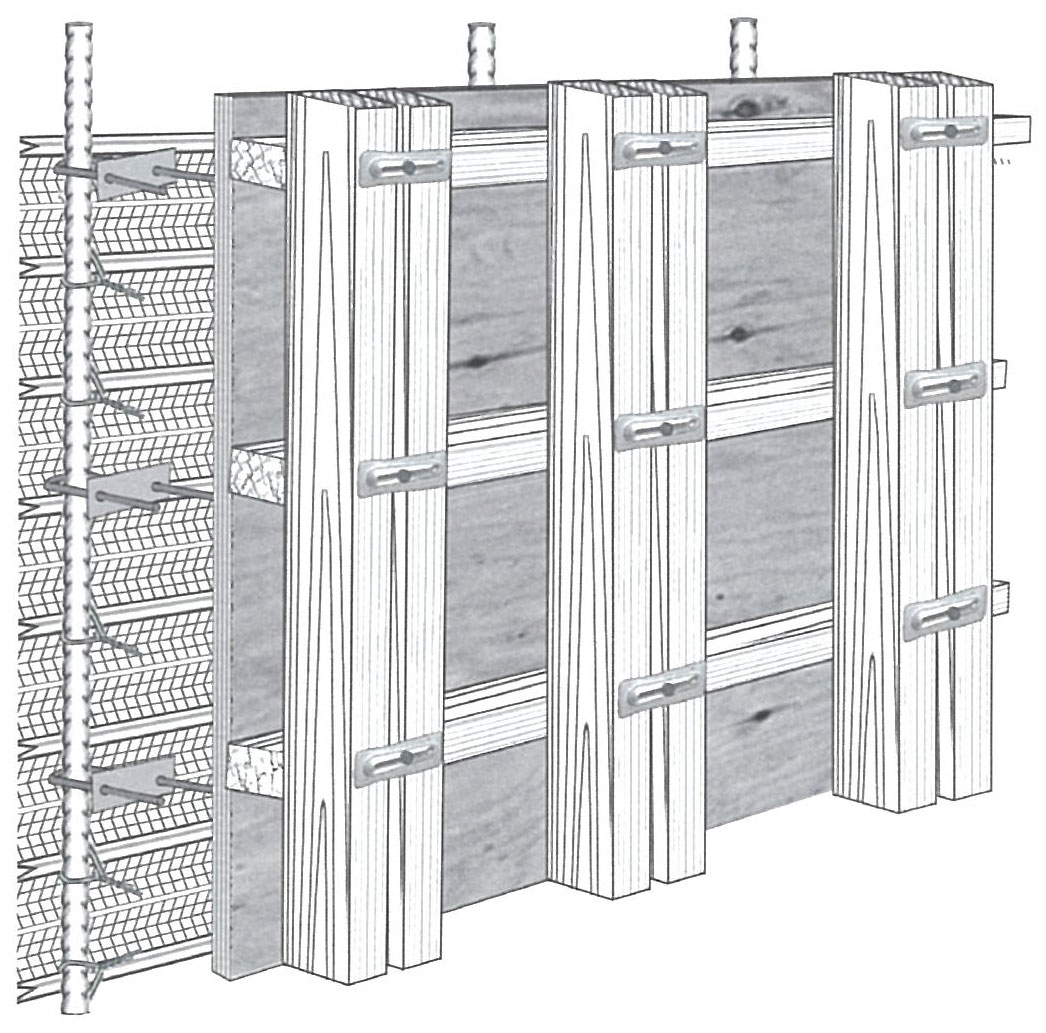

When a contractor has to form a concrete wall within a few inches of an existing structure, STAY-FORM® is an excellent product. By utilizing STAY-FORM® with rebar studs, hook ties, and a modular form system, a one-sided form or blindside wall can be constructed. If you do not have the luxury or room to strip formwork, STAY-FORM® is the right product for the job.

-

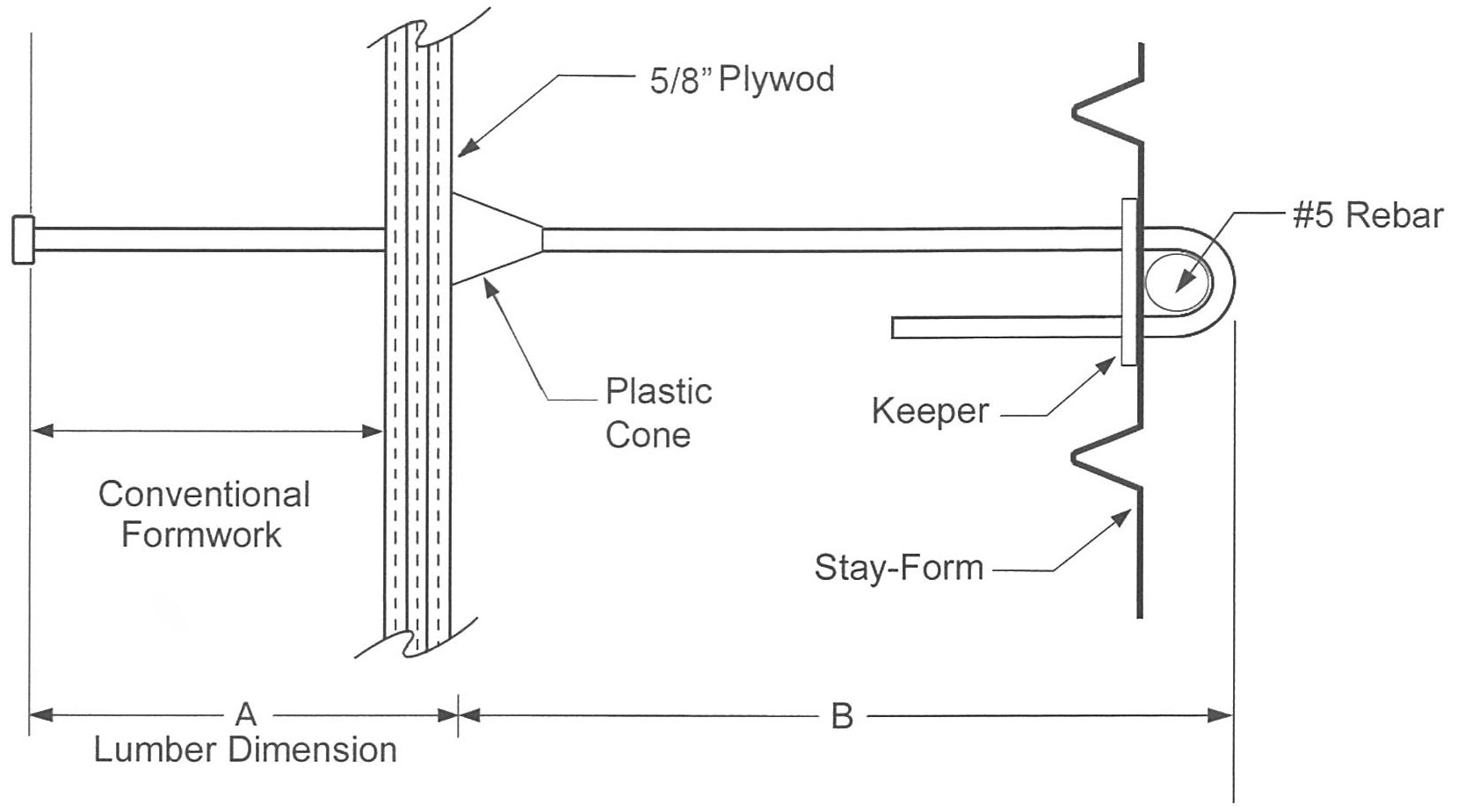

The V ribs run perpendicular to the vertical rebar studs which gives the STAY-FORM® the rigidity to withstand the concrete pressures (see detail).

-

STAY-FORM® can be slit with tin snips or handheld grinder to accommodate the rebar hook tie (see detail).

-

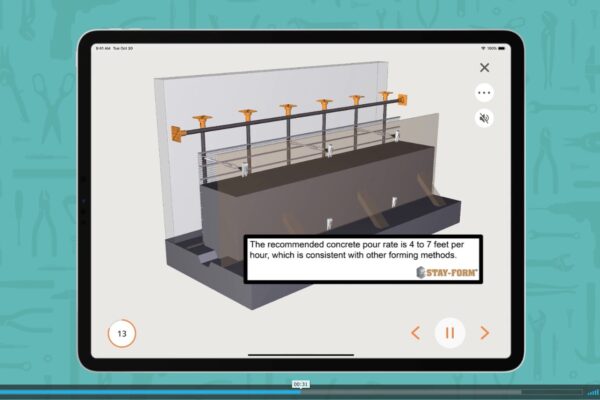

STAY-FORM® is commonly used for concrete pour rates of 4 to 7 feet per hour.*

To see more examples of blindside wall applications, visit www.amicoglobal.com and click on Project Photos. Also, check out our Stayform concrete wall forms page.